ULS Diesel Enhancer™

ULS Diesel Enhancer: The most effective, heavy duty diesel fuel system treatment for Ultra-Low Sulfur Diesels

- Save $ on expensive HPCR/CRDi/HEUI fuel injector & pump repair costs

- Eliminate or minimize injector rattle

- Protection against contaminated diesel

- Boosts diesel lubricity

- Anti-corrosion protection for fuel pumps and injectors

- Diesel Particulate Filter Compatible

- Restores power & economy

- Detergent based – no corrosive or abrasive solvents

32 fl oz treats 2000 Gallons or 7600 Liters of diesel fuel!

ULS Diesel Enhancer is the real life FIX for most Ultra Low Sulfur High Pressure Diesel problems – it cleans fuel pump and injector deposits, disperses contaminants as they form, and boosts today’s Ultra Low Sulfur Diesel fuel lubrication properties. It is a total high-pressure diesel fuel system treatment! Use it before problems arise…

ULS Diesel Enhancer

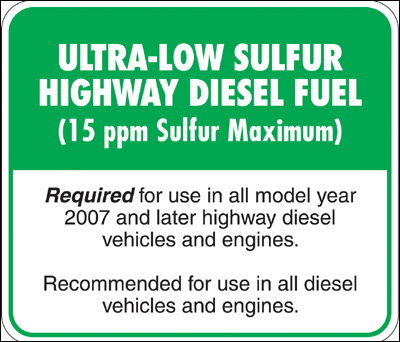

In an effort to reduce harmful emissions, the introduction of Ultra Low Sulfur Diesel, and the design and implementation of the High Pressure Diesel Injection System for diesel powered engines, including HPCR, HEUI and CRDi, high technology is now an everyday part of diesel powered engines. Variable Nozzle Injector, Pressure Amplification, Closed Loop Control, Optimized Nozzle Technology, Multiple Pulse Per Cycle, and Ad Blue Injectors are all a part of the modern technology that power most of today’s diesel-engined vehicles and machines.

However, with the higher technical performance levels required of the injection systems, the demands placed on the fuel in terms of purity and quality have also risen substantially. As a consequence, the fuel must comply with pre-defined values for viscosity and lubricity as most, if not all, of the components of the high pressure pumps and injectors are lubricated entirely by the fuel. Being free of any contamination that would lead to abrasive component damage at the extremely high pressures involved is paramount to correct fuel delivery and combustion.

Major Problems With Ultra Low Sulfur Diesel Fuel

Modern Ultra-low Sulfur Diesel can cause problems in many diesel engines

That is often where the problem starts. With modern diesel fuel having to meet the latest emission standards, stipulating that diesel fuel sulfur to be set at a very low level (from 5000ppm a few years ago, to 15ppm currently), it just happens to compound another problem…lubricity. At a time when fuel pumps and injectors rely even more on diesel fuel for lubrication, it has actually reduced. Because of the extremely fine tolerances in modern high pressure injection systems, they are incredibly susceptible to fuel contamination. Very small amounts of water or contamination will wreck pumps and injectors. High pressure injectors (HPCR/CRDi/HEUI) can often stick because of inherently low lubricity of the diesel fuel. This condition causes “Injector Rattle“ – an audible ‘machinegun-like’ noise from the engine. This condition is very serious and requires immediate attention to avoid expensive damage (Think sticking injectors causing gross over-fueling resulting in melted pistons!).

Repairing Modern Diesel Fuel Injection Systems Can Be Expensive

Prevent many Ultra-low Sulfur Diesel fuel problems – use ULS Diesel Enhancer first

Modern diesel injectors and fuel pumps are often very expensive ($2000 per injector is not uncommon). They run incredibly fine tolerances, and are highly stressed due to enormous pressures and very high temperatures. Compared to older technology diesel injection systems, they are totally unforgiving. They’re often non-repairable, so it usually means new components when total failure occurs.

Common problems with modern, High Pressure Injector systems are:

- Clogged injectors caused by contaminants – incorrect spray patterns cause a host of problems including loss of engine power, poor performance, excessive diesel smoke, excessive fuel consumption.

- Seized injectors due to lack of lubrication – caused by Ultra Low Sulfur Diesel fuel, produces over-fueling which creates detonation inside the combustion chamber, which, if not corrected, will result in melted pistons! BIG $$$

Repairing diesel injector rattle problems can be incredibly expensive! – try ULS Diesel Enhancer before you rebuild or replace your injectors!

Prevent Diesel Fuel Related Problems – Use ULS Diesel Enhancer

ULS Diesel Enhancer is the real life FIX for most High Pressure Diesel problems. ULS Diesel Enhancer cleans fuel pump and injector deposits, and disperses contaminants as they form. This highly concentrated product is proven to clean the entire fuel system, restore power and economy, boost diesel fuel lubrication properties, and provide exceptional anti-rust protection to fuel pumps and injectors. It is a total high pressure fuel system treatment! Use it before problems arise…

It is designed specifically for High Pressure Diesel systems and is recommended as a routine preventative step for all HPCR, CRDi and HEUI engines, but can be used with positive effect in any diesel powered engine, old or new. It is not recommended for gasoline engines.

ULS Diesel Enhancer is a super-concentrated formula, making it an extremely low cost solution to many diesel fuel injection problems. 8 fl oz treats up to 500 U.S. gallons (1900 liters) of fuel!

FAQ: Can I use ULS Diesel Enhancer and FTC Decarbonizer at the same time?

Yes! It’s a great idea to use FTC Decarbonizer and ULS Diesel Enhancer together! They do different jobs, yet they work remarkably well together in overcoming many potentially costly engine problems – excessive exhaust smoke, engine blow-by, low performance/high fuel consumption, etc.

Choose the most appropriate size ULS Diesel Enhancer for your particular need. Various size options are available –

ULS Diesel Enhancer is added directly to the fuel tank (diesel only).

Treatment rate: 1:8000: Add 0.15 fl oz per 10 gallons of fuel (5 mL per 40 liters of fuel)

Example:

- 10 gallons of fuel – add 0.15 fl oz (40 liters of fuel – add 5 mL)

- 40 gallons of fuel – add 0.6 fl oz (100 liters of fuel – add 12.5 mL)

- 80 gallons of fuel – add 1.2 fl oz (300 liters of fuel – add 37.5 mL)

- 150 gallons of fuel – add 2.25 fl oz (500 liters of fuel – add 62.5 mL)

As a rule of thumb, and depending on the fuel consumption rate the engine achieves, the following is usually helpful in determining which size is most suitable for your application –

- 8 fl oz – treats up to 500 gallons (1900 liters) of diesel. This is usually enough to treat diesel-powered cars, small to medium pickup trucks, small agricultural tractors & machinery, small boats, small generators, etc.

- 16 fl oz – treats up to 1000 gallons (3800 liters) of diesel. This is usually enough to treat diesel-powered mid-size pickup trucks, box trucks, small RVs, medium agricultural tractors & machinery, medium boats, generators, etc.

- 32 fl oz – treats up to 2000 gallons (7600 liters) of diesel. This is usually enough to treat diesel-powered large trucks, RVs, large agricultural tractors & machinery, large excavators, dozers, large boats, etc.

- 64 fl oz – treats up to 4000 gallons (15,000 liters) of diesel. This is usually enough to treat 2 or 3 diesel-powered trucks, or a combination of trucks and other machines, boats, etc.

- 1 Gallon – this is usually enough to treat a number of diesel-powered large trucks & machinery, combinations of various machinery and/or boats, Fleet & workshops, etc.

(32 fl oz = 946ml, 1 liter = 33.8 fl oz)

(32 fl oz = 946ml, 1 liter = 33.8 fl oz)

No Interest! No Fees!* So Easy!

With Klarna you can pay in 4 interest-free installments over 6 weeks.

With Klarna you can pay in 4 interest-free installments over 6 weeks.

Split the cost of your purchase into 4 equal payments over 6 weeks that are automatically charged to your card every 2 weeks.

How it works

- Use your own valid debit or credit card to pay (no prepaid cards).

- The initial installment is charged when we complete your order (this is usually the shipping date).

- One of the remaining installments is automatically charged to your card every 14 days after your first payment.

- There are no interest charges with Pay in 4 installments, and no fees* when you follow your automatic payment schedule.

What to do –

At Checkout

- As usual, enter your card billing address, your contact telephone number, and email address, and a shipping address if it is different from your billing address. You will need a valid phone number that can receive text messages as Klarna will text you a security code which you must enter to complete the transaction.

- Choose Yes or No for Unattended Delivery Authority.

- Select the option “Buy now, pay later”

- Click the “I have read and agree to the website Store Policy“ check box.

- Click Place Order.

- Follow the instructions provided.

- Click on Text me the code.

- Enter the code you receive.

- You may be asked to confirm your identity by entering your birth date etc.

- Then just submit the order. Done! It’s that easy!

- We will pack and ship your order within 1 business day (we try to ship the same business day).

When the order is shipped

After we confirm that the order is on its way, Klarna will charge your card for the first installment amount. Klarna will send you a notification once the payment has been processed.

Every 2 weeks

Every 14 days Klarna will automatically charge your card one of the remaining installments until the full order amount has been paid. You will be informed ahead of time.

*No fees when you pay on time

Do I have to pay Sales Tax on my order?

U.S. orders: When ordered directly from the maxodyne.com website or by phone-in order:

Delivery Address outside of Utah: No Sales Tax is payable on orders with a delivery address outside of Utah.

Delivery Address within Utah: Currently subject to a State Sales & Use Tax charge of 7.45% of the product price, i.e. Product cost = $100, Sales & Use Tax = $7.45.

Sales & Use Tax charges are automatically calculated and applied at the point of Checkout.

Shipping charges, if any, are not subject to Sales Tax.

Third party orders within the U.S.: e.g. Amazon and eBay: Sales Tax is added to the order at the point of purchase consistent with the delivery destination’s Sales Tax rate, and may include Sales Tax applied to shipping charges, if any. Sales Tax is added to the order by the Third party, and is collected and remitted to the applicable Tax Authority by the Third party.

International orders: When ordered directly from the maxodyne.com website or by phone-in order:

No U.S. Sales Tax charge applies to orders with a Delivery Address outside of the U.S.A.

There may be Duties and/or Fees applied to the order by the destination country’s Customs and Import Authority. These fees, as calculated by the local Customs Authority, are payable by the Purchaser/Importer at the time of Customs Entry.

USA Lower 48 States – From our facility in Utah, we ship daily using FedEx Standard Express as our main shipping contractor. Orders are shipped within 1 business day of receipt, and delivery is within 3 business days*. Shipping is free within the lower 48 States for orders over $50.^˜

USA Lower 48 States – From our facility in Utah, we ship daily using FedEx Standard Express as our main shipping contractor. Orders are shipped within 1 business day of receipt, and delivery is within 3 business days*. Shipping is free within the lower 48 States for orders over $50.^˜

Please note, FedEx will not deliver to USPS P.O. Box numbers as per USPS guidelines. Please provide a physical street address for shipping/delivery.

Alaska, Hawaii and Canada – we ship to Alaska, Hawaii and Canada at a subsidized rate. Shipping rates are added automatically at Checkout. All prices are in U.S. Dollars. GST & Duties/Fees may apply to Canadian purchases, payable by the purchaser as calculated by CBSA at time of entry.

Canadian customers – if it helps, we can also ship to any USA destination (Lower 48 States) for local pick-up or on-forwarding by a carrier of your choice; for example, you may have your own preferred carrier from the USA to Canada. Free shipping applies to destinations within the Lower 48 States. Ask us for details.

International Orders – We welcome our International customers! Please Contact Us for a shipping cost quote and further instructions about completing your purchase.

Please note – due to certain logistics and Federal Regulations, we are unable to ship to some Countries/Territories.

Need your product in a hurry?! Utilizing the services of FedEx and UPS, we can priority ship your product to your chosen destination*. Just contact us, tell us where you need it and when – we can then calculate the cost and advise you of the shipping details. All prices are in U.S. Dollars.

*We reserve the right to use other shipping suppliers and services as we deem necessary from time to time, depending on prevailing circumstances. Delivery schedules may be affected by conditions beyond our control.

^A $10 shipping charge applies for orders below $50 excluding tax.

˜Applies to retail quantities only. For commercial quantities, please contact us for further details.

Duramax problems solved

“My 2008 Chevrolet Duramax, with only 129,000 miles, was running badly and intermittently blowing clouds of black smoke at highway speeds. It had bad power loss above 65 mph – usually no throttle response above this speed. Also, it felt and sounded like the turbo was constantly surging at any speed. Over the last couple months I’ve been using FTC Decarbonizer and ULS Diesel Enhancer in the diesel, and it has made a tremendous difference! No black smoke! Running so much smoother, full power again, and I’m getting 2.5 mpg better fuel mileage! I’m looking forward to the results I get from the Flushing Oil Concentrate. Great products that do as you said they would. Really appreciate your help.”

Ryan D, Lawrenceburg, TN

Preventative maintenance, great results

“I started using the products about 6 years ago when I needed to rejuvenate a Yanmar turbo 4-cylinder engine on a newly purchase 27 year old sailboat. The engine was in very poor condition – the exhaust smoke was black, and it had little torque. As it’s a marine engine with little chance of working “hard”, it did take quite a while of using the FTC Decarbonizer and Cleanpower, along with 3 oil flushes over time using Flushing Oil Concentrate to get the engine back to as new condition. As you know, the turbo was mechanically damaged, so I replaced it.

Seeing the wonders these product can provide I started using them on my two V6 Mercedes diesel-engined vehicles. These are late model vehicles with diesel particulate filters and exhaust fuel treatment additive (DEF).

I bought both of these vehicles, used, with low kilometers. I now have 110,000 kilometers on one car, and the SUV has reached 160,000 kilometers. Both engines run with FTC Decarbonizer and ULS Diesel Enhancer. When I change the oil, I use the Flushing Oil Concentrate as you recommend. I always use high quality full synthetic oil in these engines.

I can see that the engine oil is soot/carbon free, and the oil remains clean and honey colored for a period of time.

Result is my cars perform superbly with unbelievable acceleration (for a diesel) and are very economical on fuel.

So for me these products are preventive maintenance and I know it is not a scam with the results I get.”

Jacques L, Quebec, Canada

Remarkable improvement

“I do not have enough good to say about these products!!

I own a 2002 Peugeot 308 with a 2.0 turbo diesel. (mileage: 290K kilometers/180k miles)

When I purchased this vehicle it was at 150k (93K miles) and felt under-powered due to the mileage.

I contacted Maxodyne and spoke with Scott, and asked if he felt their products could help my small diesel car. After asking me some questions about the car, he suggested I use 3 products. I used the oil flushing treatment, and I have since been running the FTC Decarbonizer and the ULS Diesel Enhancer in every tank.

Scott is extremely knowledgeable and helpful when it came to helping me sort my concerns and needs with this little diesel. (Do not hesitate to contact him, he is a joy to work with.)

Frankly, I am still in awe of the vast difference in the throttle response and power difference while driving this little car, even after the first two treatments.

When I first purchased this vehicle, before the treatments, I was getting an average of 950km per 55L tank of fuel (5.7L/100km, or 41MPG). Since treating the engine with these products I have been getting 1150-1200km (4.6L/100km, or 51MPG) from the same tank. Almost a 25% increase in fuel economy!!

These products pay for themselves every time I need to go to the pump.

I am a firm believer in these products, and will be using them in all my diesel vehicles from now on.”

Brian M. Queensland, Australia

Much quieter diesel engine

“I finally got to put the ULS Diesel Enhancer in my Toyota Land Cruiser. It has around 252,000 miles and yesterday when I first put it in the tank I did not notice any difference, but today when I started it I noticed that the motor was more quiet than it usually is at first start. And my friend who used it also in his diesel Land Cruiser found a big difference in power and also said his is also a much more quiet motor.”

Johannes G. Iceland, Europe

Products actually work

“First off, this business is awesome! There aren’t many companies that thank you with a hand written letter. I have used some of their additives for several years now and I have to say they actually work and make a noticeable difference. I have always been skeptical of additives in anything other than gas/diesel fuels. With that said I still believe a lot of additives on the market are a waste of money except the ones from Maxodyne. I have used the AW-10 Antiwear and the ULS Diesel Enhancer (and now about to add the FTC Decarbonizer to the list) and they made a noticeable difference! I am an Amsoil dealer and in my opinion the Amsoil is more than enough to keep an engine clean and running great, but the AW-10 Antiwear made a huge difference with the Amsoil in my 6.7L Powerstroke as well as my wife’s Explorer with the Eco-boost. Thanks again!”

Ryan J, Lake View, AL

No problems in 3 years

“I’ve been using your products for coming up 3 years, and I’m amazed at how strong my Freightliner still is. It just keeps running with no problems, and I believe it’s your products that are keeping it that way. Not once have I been pulled up on the side of the road, not once!! The FTC Decarbonizer, Flushing Oil Concentrate and ULS Diesel Enhancer do a great job. I haven’t touched the injectors at all, oil pressure is strong all the time, engine runs smooth and strong, the initial blowby settled down and has never come back. Thanks for great products, I really believe in them.”

Howard B. Monroe, TN

VW T5TDi cleaned up

“I imported this 2005 turbo-diesel VW California from Germany and just returned from 9,500 kilometers to Baja, Mexico. I found the FTC Decarbonizer cleaned up the engine and smoothed out the idle. I hadn’t used the AW10 Antiwear before, but my initial reaction is WWOOWW!!! The engine revs smoother, dead quiet – all that is advertised. I’ve not done a mileage comparison as yet, but the ease of the engine tells me it is rolling easier which can’t be a problem. I’m looking forward to seeing the results from the diesel enhancer now.”

Doug C. Victoria, BC Canada

Mercedes Benz S-Class improvement

“Our 2012 S350 Benz (V6, 3.0 Liter diesel) has only 53,000 miles, but was blowing a lot of black exhaust smoke, and was burning oil. We bought the Diesel Performance Pack and within just a few weeks the exhaust smoke has reduced significantly, as well as the oil burning. I suspect that will continue to improve the more we drive it. Another benefit we’ve noticed is the fuel economy has gotten better by about 10%, at 90mph highway driving and we’re getting 34mpg!”

(Diesel Performance Pack contains FTC Decarbonizer, ULS Diesel Enhancer, and AW10 Antiwear)

Dan D. Olympia, WA

ISX15 Oil consumption fixed

“My ISX 15 Cummins has around 750,000 miles, and started using a lot of oil over the past few months or so. The cost of an inframe overhaul was not good. I decided to go ahead and order your products and did the oil change flush about 10 days ago. Great stuff! Usually the new oil is black again right after I get the oil changed. Now, 10 days on the road, and it’s still clean on the dipstick! That’s crazy! The oil consumption has now dropped back to almost nothing. The FTC Decarbonizer and ULS Diesel Enhancer are making a huge difference too. I’m sure the rings and injectors have cleaned up. The engine is running a ton smoother, it’s up on power, and miles per gallon is up too. It’s like it’s opened up, got everything cleaned up. I’m noticing a real difference, it’s crazy! I’m very happy with the products, I’ll keep using them, keep this girl on the road. I’ve already told a lot of other drivers about them. Thanks for your help!”

Jean I, Lorain, OH

Twin Diesel Marine Cummins

“We have a recreational boat with twin 8L Cummins marine engines. They’re 21 years old, but only have 1780 hours total. Over the years we’ve done regular oil changes and maintenance. We thought that was enough, but it seems that was the downfall. The boat sits a lot (obviously) and has a lot of long periods of low speed/low load getting it through the ship canal and locks to get to the ocean. Summer of 2021, one engine started to smoke a bit, and would run on only 5 cylinders for a few minutes after starting. Replaced the injectors hoping that would fix it. It didn’t. Last summer (2022) it got worse – that engine was slow to start, smoked more, and started using a lot of oil. Fall of 2022, we took the boat out after servicing for a short run. It began to knock and bang HORRIBLY, so we limped home. Tested compression, the Starboard engine #1 cylinder had 0 compression. At tear down, it was blatantly obvious that the rings had carboned up and broken, then the piston slapped around and broke, destroying the piston and liner. With only 1780 hours!

We in-framed that engine, and to preserve the port engine which was smoking and getting harder to start, we have used Flushing Oil Concentrate, and are using FTC Decarbonizer and ULS Diesel Enhancer in the fuel tanks, and AW10 Antiwear in the old port engine. Results so far – the engine oil in the port engine remains very clean after the flush, the starboard/rebuilt engine will get a flush after it has bedded in. After adding the FTC Decarbonizer to the fuel, I noticed RPM picked up immediately and the engines idled more smoothly. Last Friday (before fuel treatment), the Starboard engine (just rebuilt) turned 2515 RPM WOT and the Port turned 2435 RPM WOT. Today, after adding the diesel treatment, both engines turned 2530- so we are picking up a few horsepower for sure! I’m sure the AW10 is helping with that also! With these engines, gaining 100 RPM is not insignificant. I can’t wait to see further improvement with a little more time.”

John E, Bellevue, WA

1978 Blue Bird Wanderlodge

“My 1978 Blue Bird Wanderlodge had been having a white exhaust smoke problem for quite a long time, and it was slowly getting worse, and it just ran rough. It didn’t miss, and the power seemed normal. It has the Cat 3208 engine, with only 100,000 original miles. It sits a lot, I don’t drive it as much as I’d like. About a year ago I had the fuel pump rebuilt. Anyway, I bought the Stop Smoke Diesel Pack, and started using the Diesel Enhancer right away. I then used the Oil Flush. After driving for just a little while the white exhaust smoke has cut right back to almost nothing now, and the engine is certainly running much better, smoother and quieter. I’ve started adding the FTC Decarbonizer to the fuel also, and I expect it will continue to improve even more. Many thanks for these great products, they’ve honestly helped a lot.“

(Stop Smoke Diesel Pack contains FTC Decarbonizer, ULS Diesel Enhancer, and Flushing Oil Concentrate)

Manzie L, Naples, FL

Land Rover Discovery diesel

“Just wanted to let you know that I’ve been using your diesel additives for three fills now and THEY REALLY WORK! But of course you already know that.

My old Land Rover Disco 3 diesel is running really smoothly and definitely has considerably more power.

The difference is clearly noticeable — if she was a horse, you’d say no way is she going to the knackers!

A new lease on life. Many thanks!”

Bill G, Obi Obi, QLD, Australia

6.7 Powerstroke never been better!

“Our 2013 F250 Lariat, 6.7 Powerstroke has had problems for a while now. It’s got pretty low miles for its age, and it was down on power, bad exhaust smoke, noisy idle. I’ve owned it since new, I’m a very particular person, it’s always been serviced above the recommendations. I’ve tried many products to fix the problems its been having, but with no luck at all. After talking to you about it, I ordered the Stop Smoke Diesel Pack. I admit I was a bit skeptical about it, but I’ve tried just about everything else, I might as well give your products a shot. I tell you, these products work! It’s almost unbelievable! It has NEVER idled so smooth and so very quiet. Never! The acceleration and power is better than it has EVER been! The exhaust smoke has disappeared, I can definitely feel the turbo working again too. It’s a different truck, I’m amazed about how much better it is. Amazing results from these products, I can totally recommend them, they work!“

John D, Rochester, NY

Great service!

“Thank you! Thanks for all your help and information along the way. And I really appreciate you getting my order shipped so quickly. I just received a notice from Fed Ex that the package is out for delivery today – that’s some world class service! (Ordered Friday night, shipped Saturday, out for delivery Monday)”

Brian F, Austin, TX

Night to day difference

“I got your Stop Smoke Diesel Pack for my old 2006 Ram. 5.9. It’s got 286,000 miles, and mostly it is running fine, or so I thought. You can really tell the difference from using the fuel treatments (FTC Decarbonizer and ULS Diesel Enhancer), it’s like night to day! I’ve not done the oil flush yet, but once I get to doing it I will let you know how that goes and keep you posted.”

Adrian R, Reno, NV

Runs like brand new!

"...the money it has saved me over the years, wouldn't run without it..."

"I've been using your ULS Diesel Enhancer in my 2006 Dodge Ram 2500 5.9 Cummins for many years now. It's been a lifesaver! It still runs like brand new. I've never had a single problem with the engine in all the time I've used it. I firmly believe it's a great deal - the money it has saved me over the years. Friends have spent thousands on major repairs compared to maybe a couple hundred for the price of this product over the years for me. It honestly is good stuff. Wouldn't run without it."

Lawrence B, Spanish Fork, UT

So much better!

"I've been using these products for years with good results every time. A while ago I picked up a secondhand small single-cylinder diesel-powered inverter generator, and it was running like a dog. I did the usual bits and pieces to it and thought it was running much better after that. After a while I thought I might as well put some ULS Diesel Enhancer in the tank to see if it made any difference. I didn't expect much. But within no time it was running so much better, so much smoother. It was incredible! I never thought it could run like it now does. It's incredible! Had to tell you!"

Terry H, Fairhope, AL